We take thousands of scanning electron micrographs every year to document, characterize, and evaluate our surfaces. This collection contains our favorite images from the year, highlighting patterns from our ongoing research initiatives as well as the natural sources that help inspire us.

Developing patterns

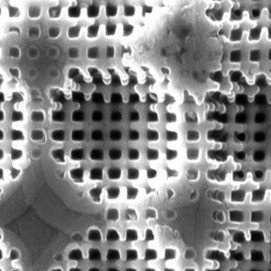

A look at some patterns currently being developed

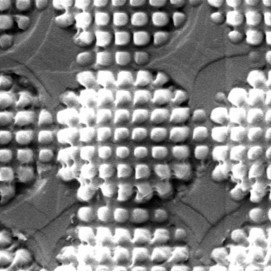

500nm bumps indented into a copper mold

400nm features replicated into a UV-cured polymer

5µm features replicated into a UV-cured polymer

Interwoven indents created in a nickel mold

Multi-scale features replicated into a UV-cured polymer

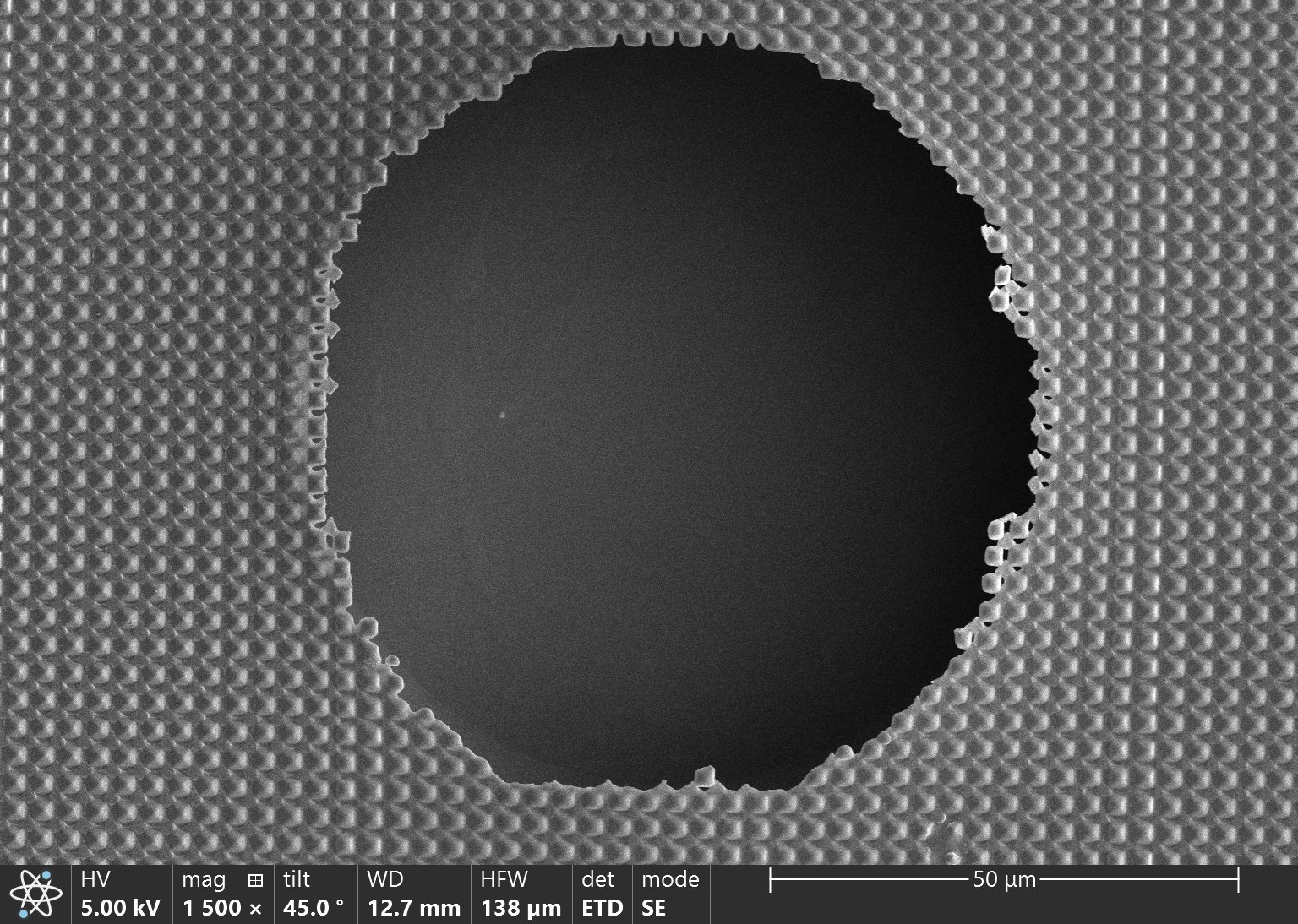

Replica Defects

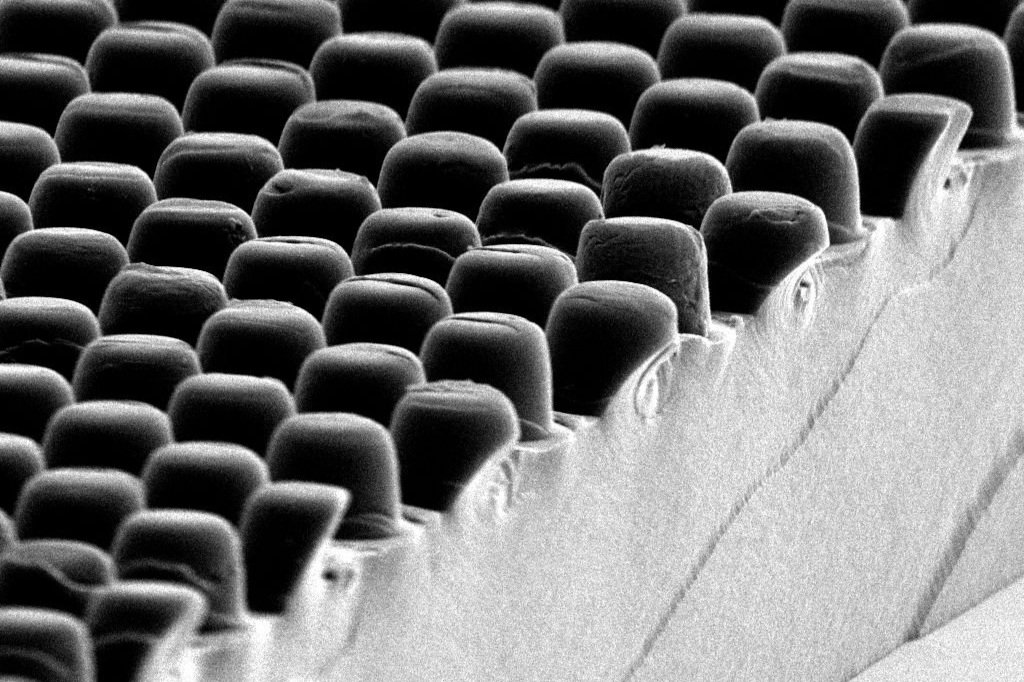

As shown by the edge of this replica, the defects stand out in otherwise uniform patterns.

Areas where resist didn't fill, creating voids in the replica

A thin portion of resist resulting in a lack of feature fill (left) and a scratch in the resist creating loose polymer gumdrops (right)

Wrinkles and bubbles in the replicated polymer

Occasionally hard particles in the mold will damage the indenting tool, leading to missing features

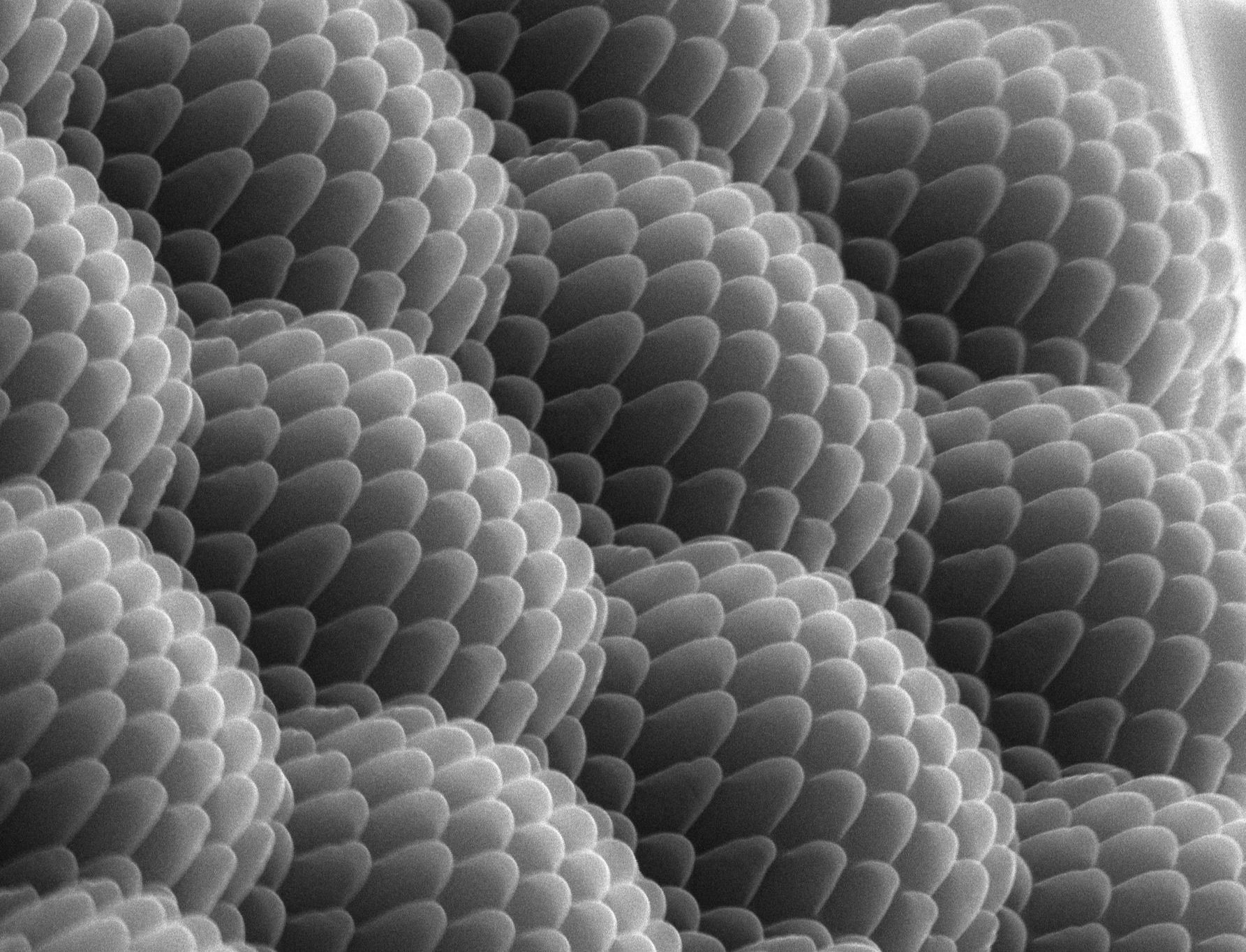

Insects

These small organisms often possess nanopatterns that help them survive. Scientists study them to enhance their understanding of nanostructures.

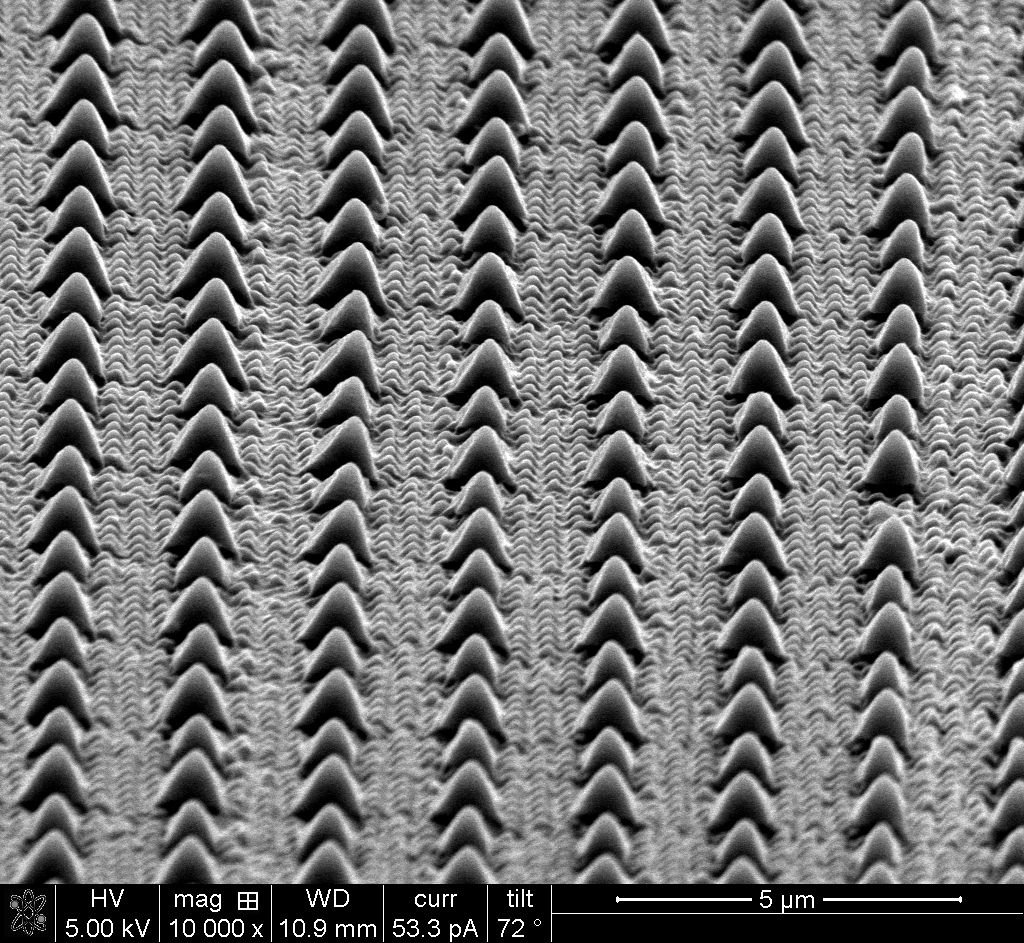

The moth-eye effect gets its name from the hierarchical structures that can be found on the top of a moth's eye. These bio-inspired surfaces can be used to supress reflections on optics or increase transmission through solar panels.

Comparison of a textured moth's eye (left) and the smooth eye of a green june beetle (right).

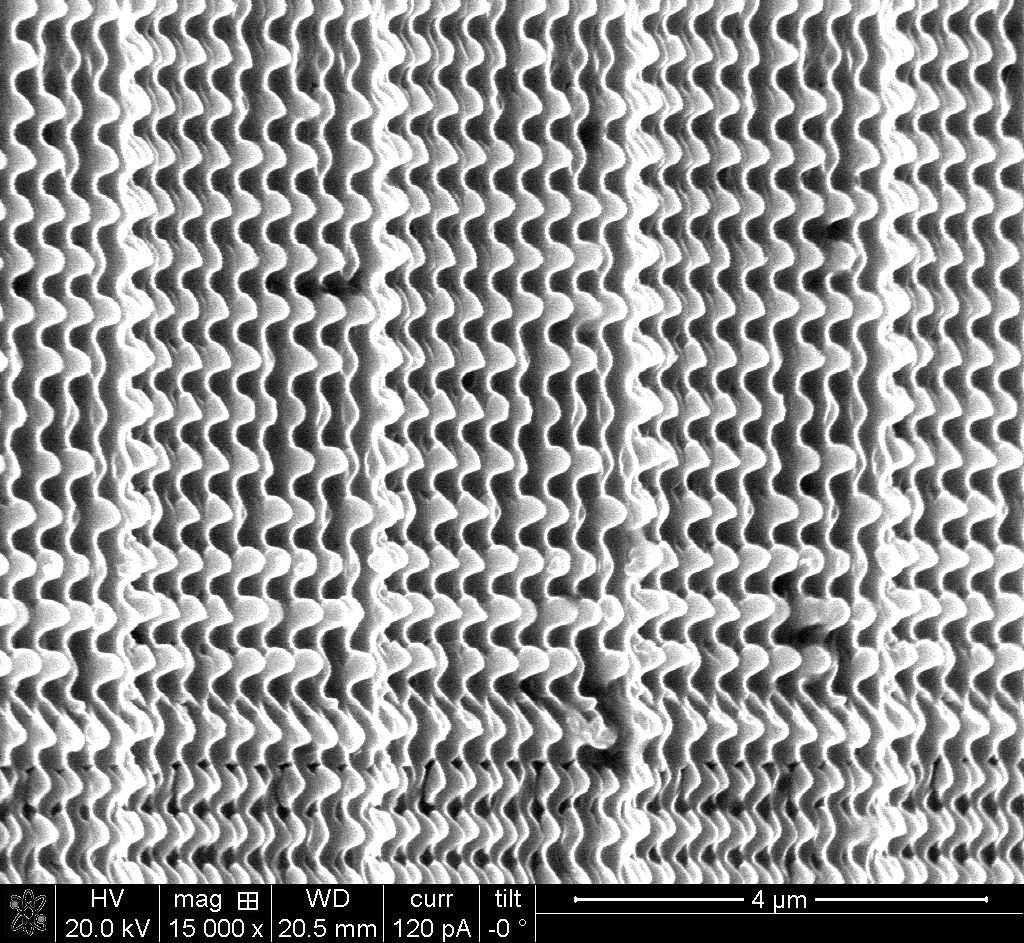

Biocidal nanopillars seen on a cicada wing (top) and the scales from a moth's wing (bottom).

These images were taken by Lauren Micklow, Nicky Scott, Brenna Tryon, and Malcolm Shumel at the North Carolina State University Analytical Instrumentation Facility using an FEI Quanta 3D DualBeam SEM/FIB or a Helios 5 Hydra DualBeam SEM/pFIB.