Nanocoining: High-Speed Nanopatterning

Nanocoining enables scalable nanomanufacturing by creating seamless nanopatterned cylindrical molds for roll-to-roll nanoimprint lithography (R2R NIL). See our Molds page for specs.

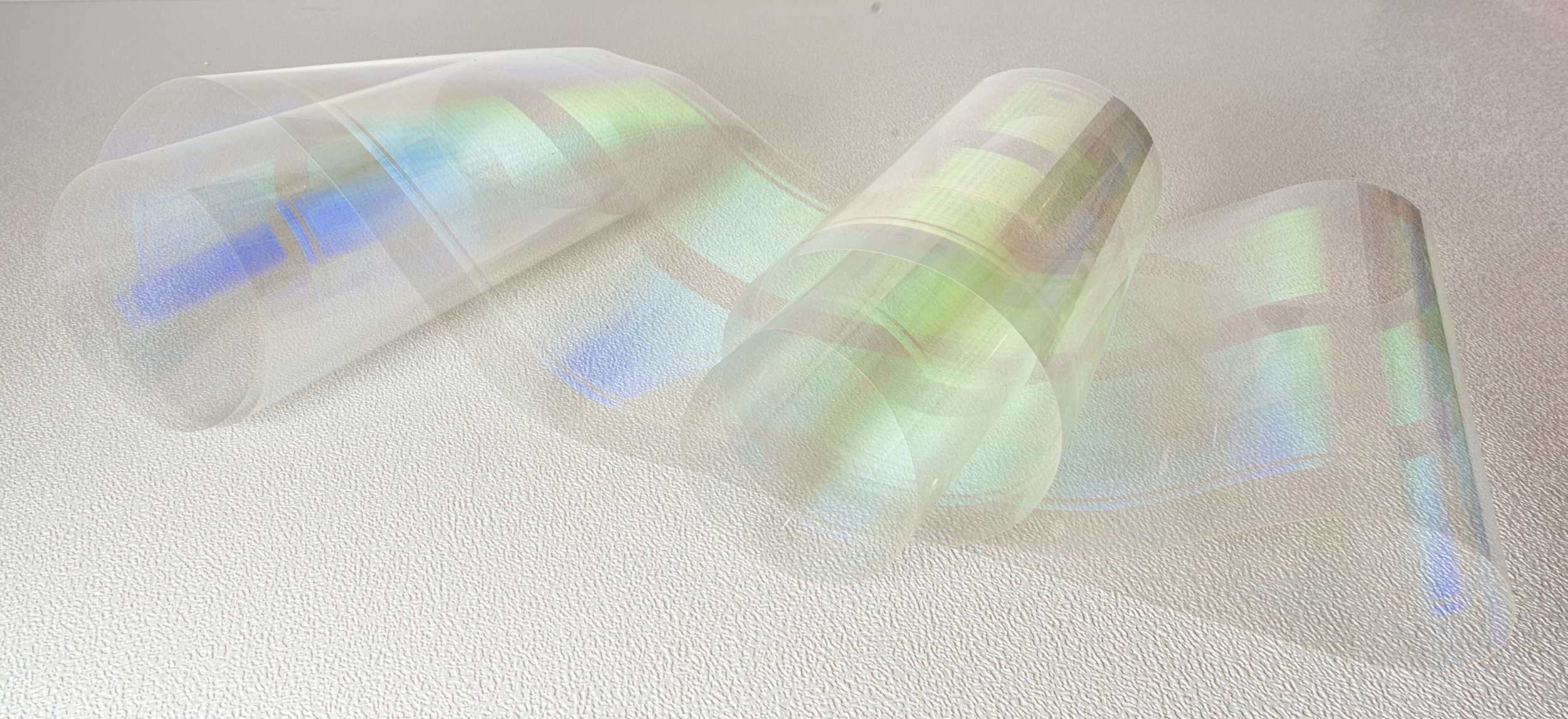

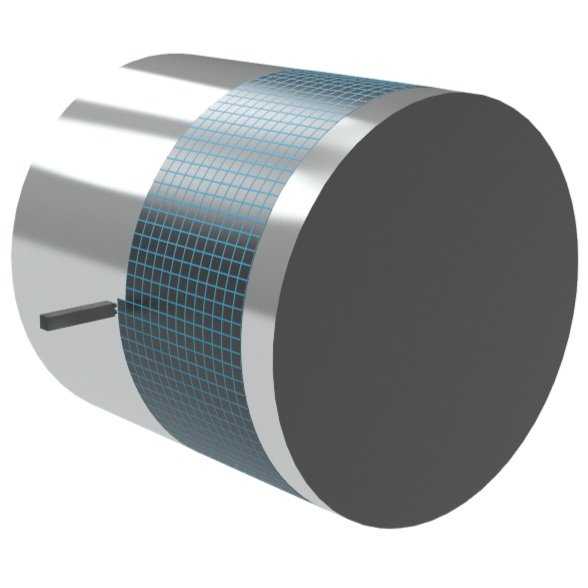

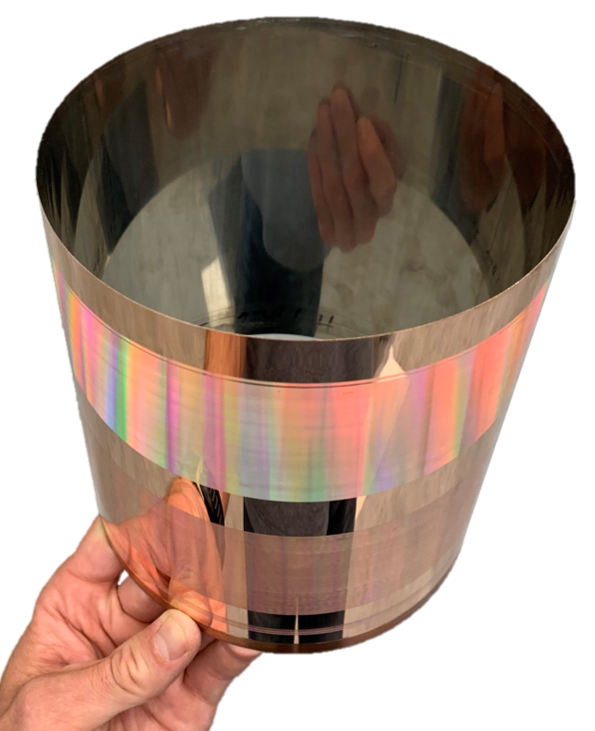

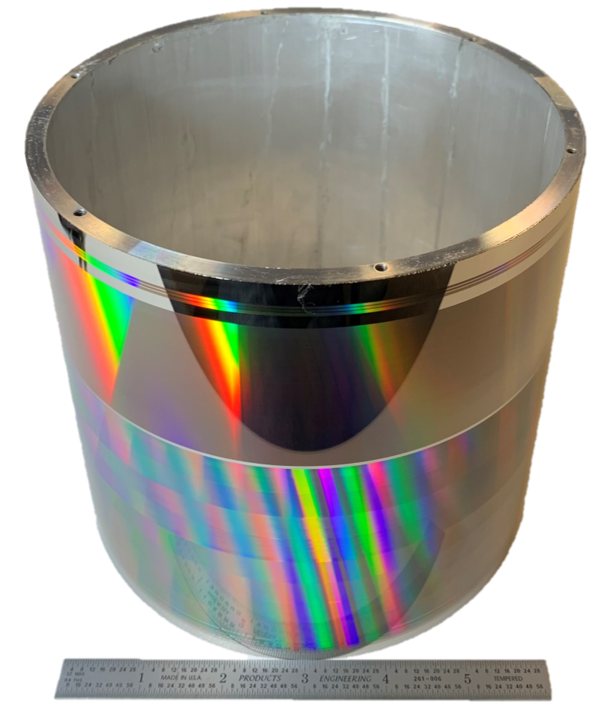

Nanocoined R2R mold

Nanocoining is a patented process that seamlessly indents micro or nanopatterns around the outside of a cylindrical drum or sleeve more than 500 times faster than electron-beam lithography. These molds are ideal for R2R NIL; they can also be segmented to make flexible master molds for batch NIL processes. Our drum molds were recently used to nanopattern over 500 feet of polymer film using R2R thermal embossing at MicroContinuum, Inc. as shown below.

Process Overview

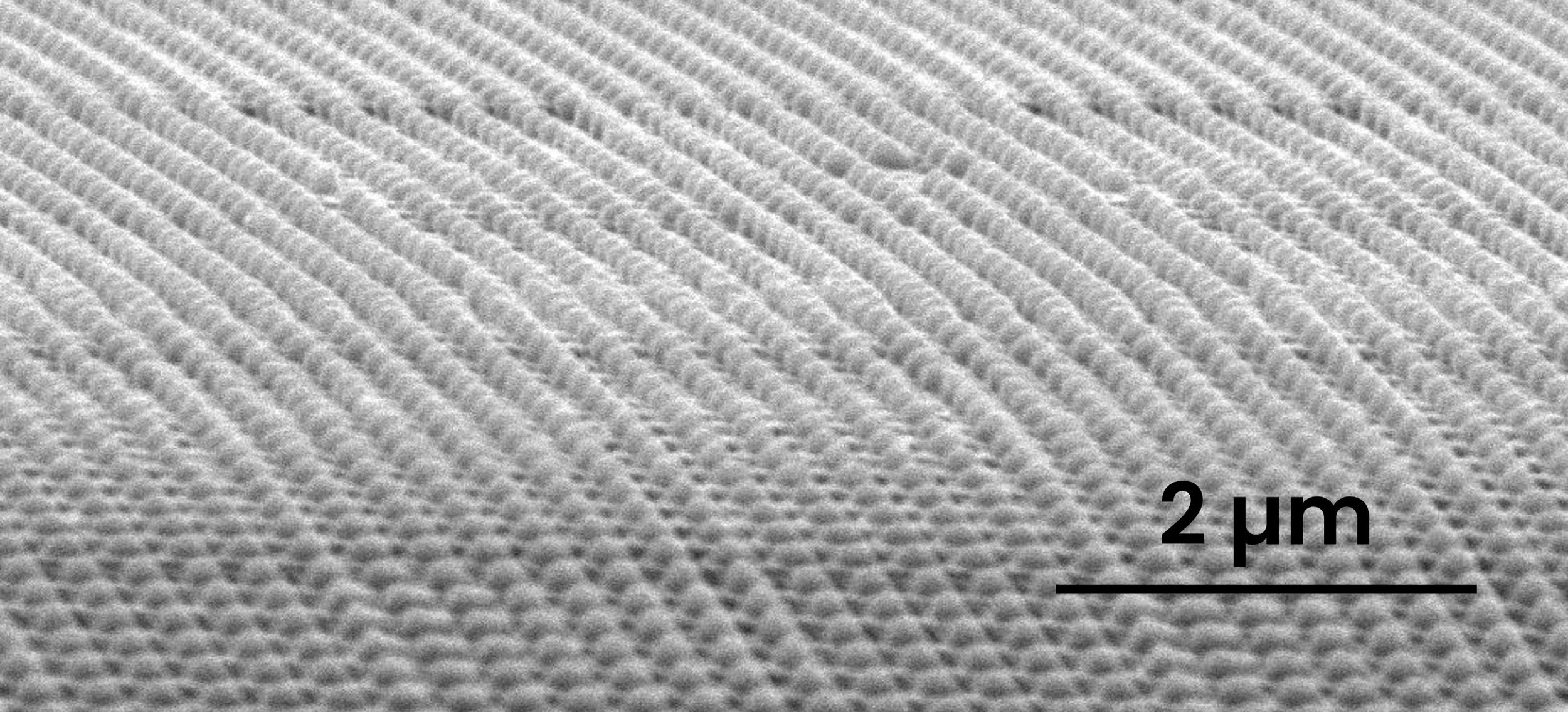

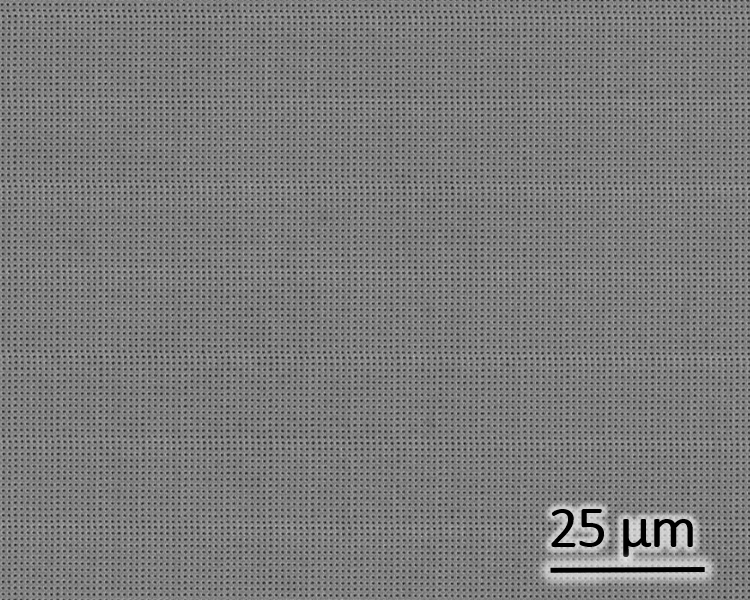

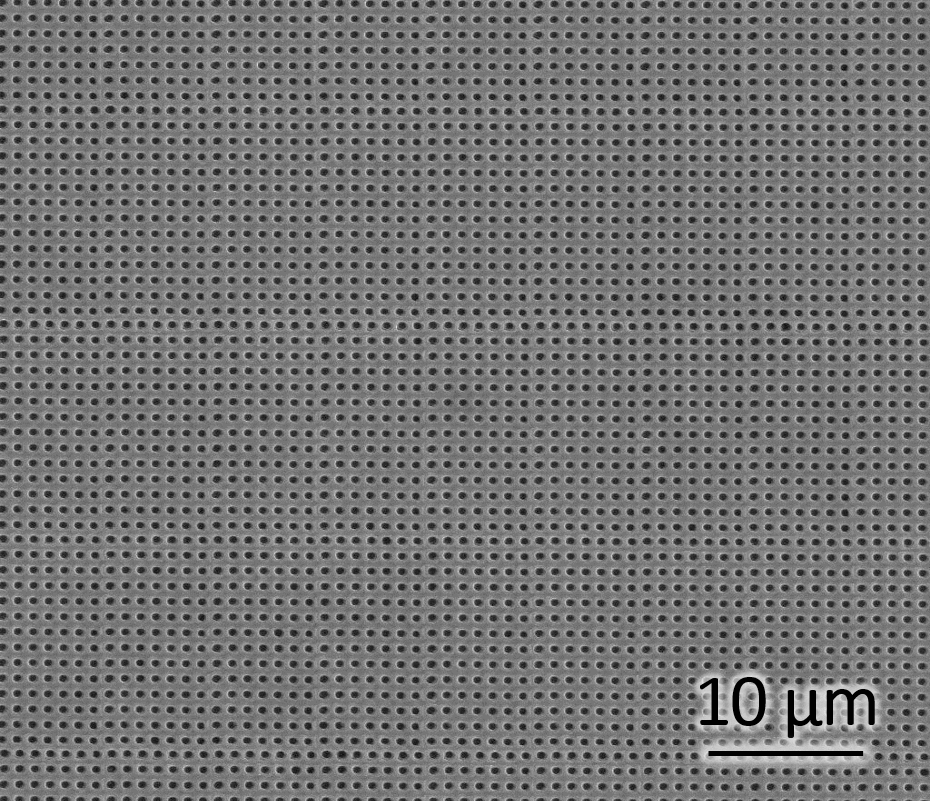

During nanocoining, an ultrasonic actuator indents a nanopatterned diamond die into the outside of a rotating metal drum about 45,000 times per second to rapidly cover the surface of the drum mold with a seamless spiral of indented features.

Competitive Advantage

Nanocoining’s competitive advantage lies in its unique ability to nanopattern:

More than 500 times faster than electron-beam lithography. Nanocoining’s exceptionally high coverage rate, shown on the right, enables large-area nanopatterning that is infeasible with traditional lithography techniques due to their low speed and high cost.

Seamlessly around cylindrical R2R NIL molds. Many competing processes pattern flat shims that must be wrapped around a cylinder for R2R processing, resulting in a seam that is undesirable for many applications.

Without chemical processes like resist development and etching.

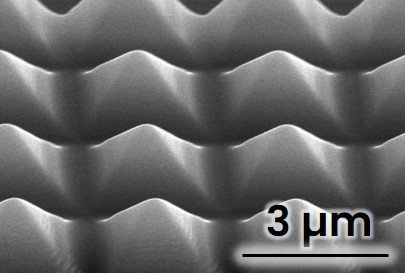

With control of the 3D feature shape. Traditional lithography produces binary features instead of 3D feature shapes.

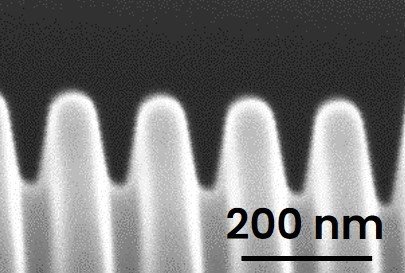

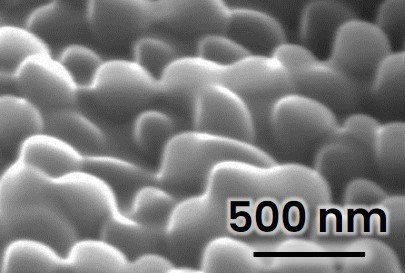

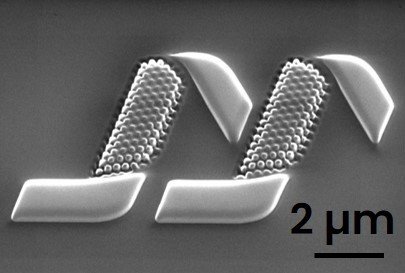

Diamond Dies

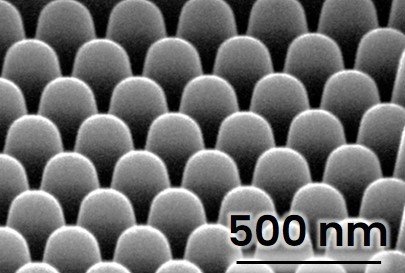

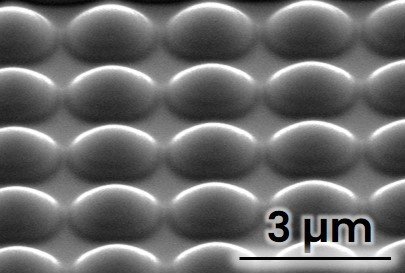

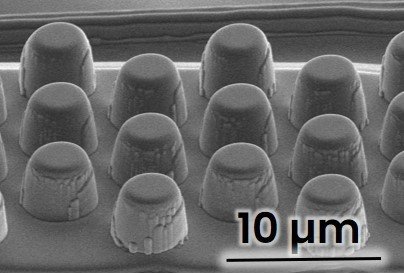

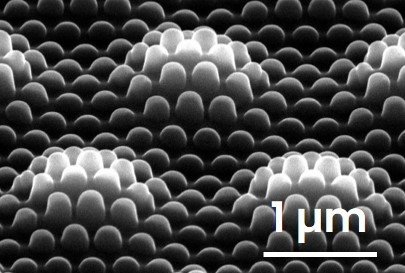

Smart Material Solutions has developed expertise in the nanopatterning of diamond for the first step of the nanocoining process. Patterns include periodic, stochastic, and arbitrary features with a range of shapes (pillars, gratings) and sizes (~100 nm to 5 µm pitch). We have also produced hierarchical features with nanofeatures on top of microfeatures. More information about our features can be found on our Molds page.

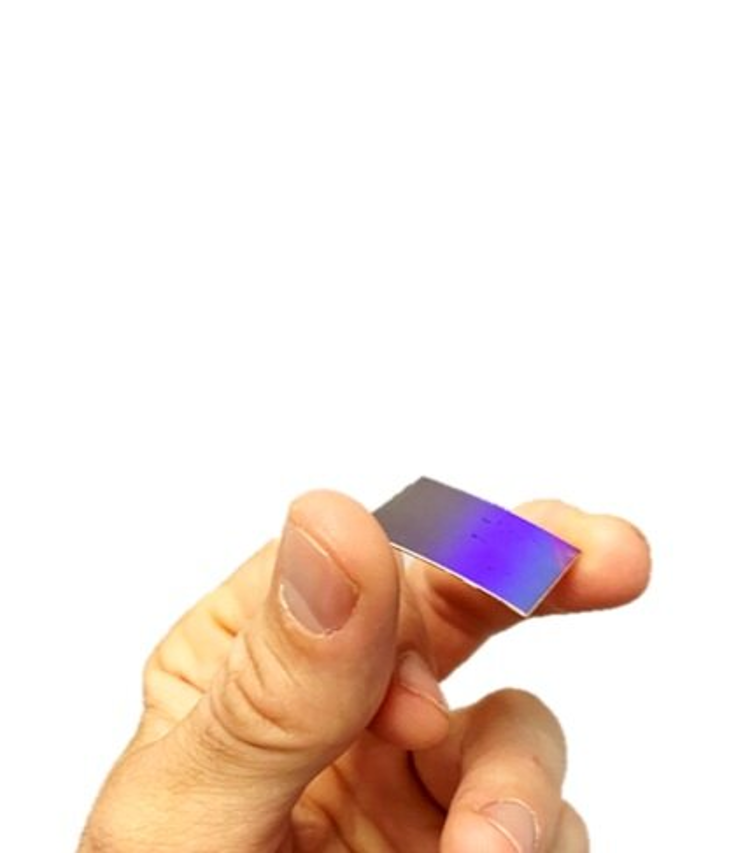

Indented Molds

Metal molds can be made in the form of a solid cylinder, seamless sleeve, foil shim, or supported flat in order to fit the customer’s imprinting tool. Presently cylinder length and diameter is limited to 160 mm and mold materials include aluminum, copper, and high-phosphorous nickel. More information about our molds can be found on our Molds page.