Throughout the year, we go to our local university and use their microscopes to image samples and pattern our diamond dies. I personally went over 60 times this year! Most of the images we take are utilitarian, designed to extract profiles or reveal experiment results. But sometimes science and art intersect, resulting in the images you see below.

Protective Features

Some of our recent work centers around creating features to protect the micro and nanostructures for applications where durability is important.

A metal mold with a hierarchical pattern and a protective grating

A polymer replica, with a hierarchical pattern protected by a grating

Photomasks

To determine which polymers to use with our Nanocoined photomasks, we ran initial experiments with standard photomasks made at NC State. One of our less ideal polymers created features with high aspect ratios.

Pattern inversion

The patterns on molds created with Nanocoining are inward facing due to the nature of the indenting process, resulting in outward-facing features in our polymer replicas. To create the inward-facing features in a polymer replica as seen below, we had to develop a method to invert our molds.

A second-generation polymer replica. This replica has features that are wells instead of bumps.

Imprint Edges

At the edge of UV-cured imprints, the polymer doesn’t always fully fill between the substrate and mold, resulting in voids next to uniform patterns.

Miscellaneous

A wrinkle in a polymer replica

The fibers and printed letters of a $100 bill

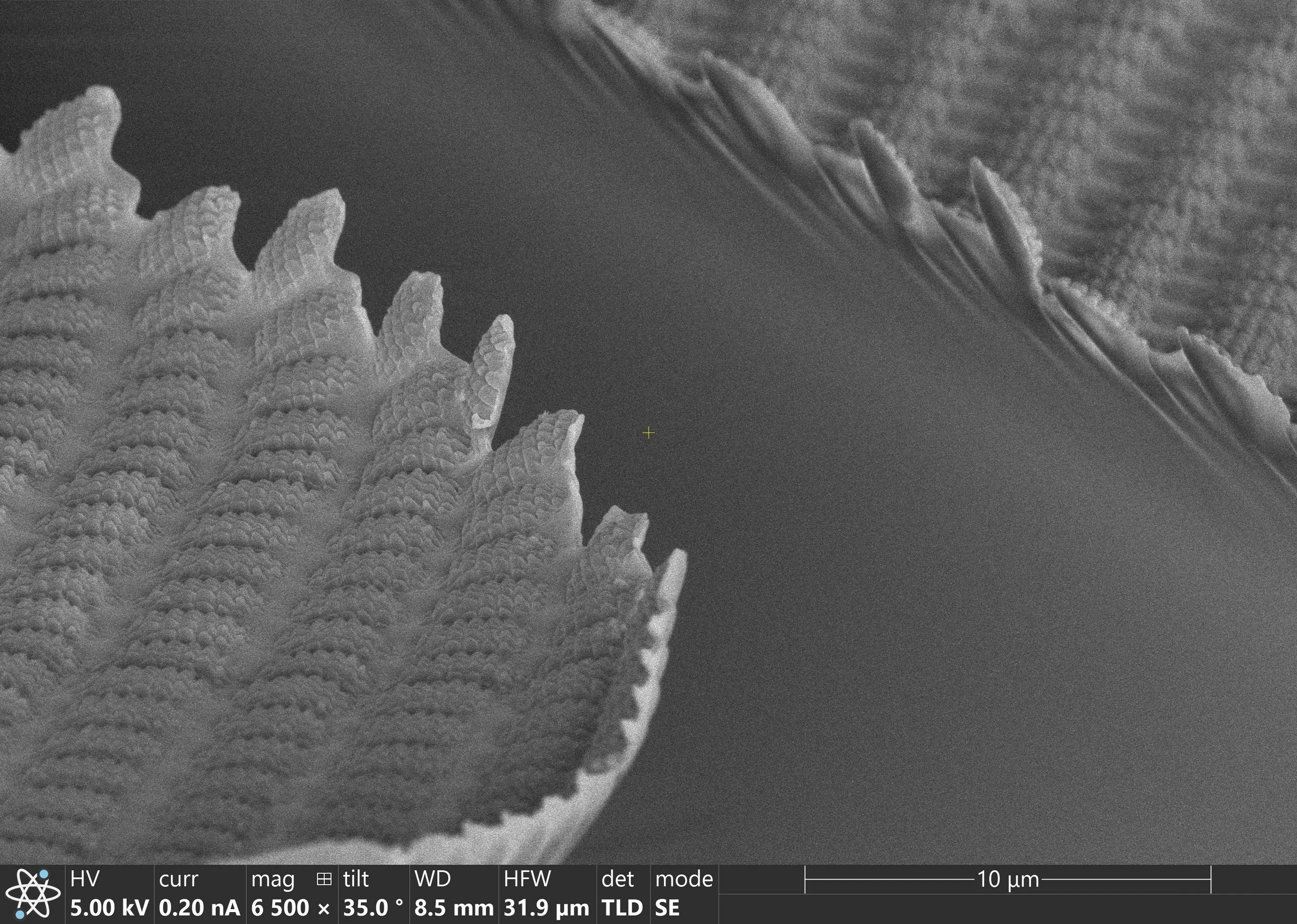

A dragonfly wing

A cuticular spike in a dragonfly wing

Antimicrobial nanostructure in a dragonfly wing

These images were taken by Lauren Micklow at the North Carolina State University Analytical Instrumentation Facility using a Quanta 3D DualBeam SEM/FIB, a Helios 5 Hydra DualBeam SEM/pFIB, or a SCIOS 2 DualBeam SEM/FIB.